Kinematic Optimization of an Underactuated Anthropomorphic Prosthetic Hand

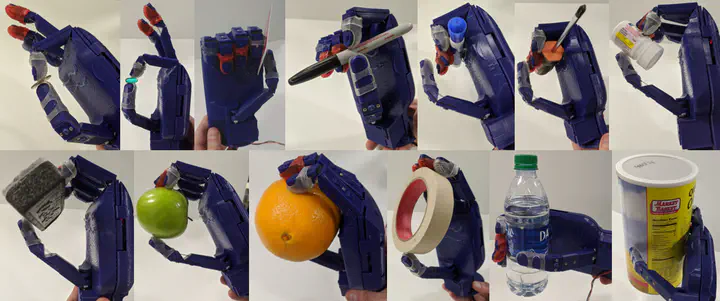

The hand can grasp a wide range of everyday objects, ranging in size from 0.085 cm to 12.8 cm

The hand can grasp a wide range of everyday objects, ranging in size from 0.085 cm to 12.8 cm

Abstract

The human hand serves as an inspiration for robotic grippers. However, the dimensions of the human hand evolved under a different set of constraints and requirements than that of robots today. This paper discusses a method of kinematically optimizing the design of an anthropomorphic robotic hand. We focus on maximizing the workspace intersection of the thumb and the other fingers as well as maximizing the size of the largest graspable object. We perform this optimization and use the resulting dimensions to construct a flexible, underactuated 3D printed prototype. We verify the results of the optimization through experimentation, demonstrating that the optimized hand is capable of grasping objects ranging from less than 1 mm to 12.8 cm in diameter with a high degree of reliability. The hand is lightweight and inexpensive, weighing 333 g and costing less than 175 USD, and strong enough to lift over 1.1 lb (500 g). We demonstrate that the optimized hand outperforms an open-source 3D printed anthropomorphic hand on multiple tasks. Finally, we demonstrate the performance of our hand by employing a classification-based user intent decision system which predicts the grasp type using real-time electromyographic (EMG) activity patterns.